Brymec’s new VOX Acoustic Waste Solutions

Performing Well Under Pressure: The New Brymec PRV

You can count on Brymec for PVC We’re not going anywhere

Unveiling Our Innovative New Website & MyBrymec Portal

Correct Use of Thermal Insulation

Carbon Steel vs. Stainless Steel

Digital tools for construction: We're ready when you are

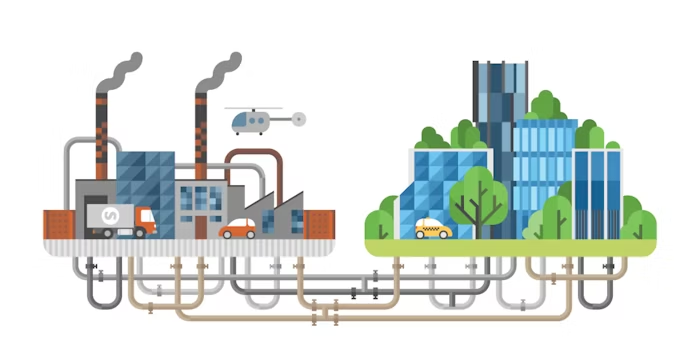

District Heating: Part of our decarbonised future